Injection Packer

- Home

- Injection Packer

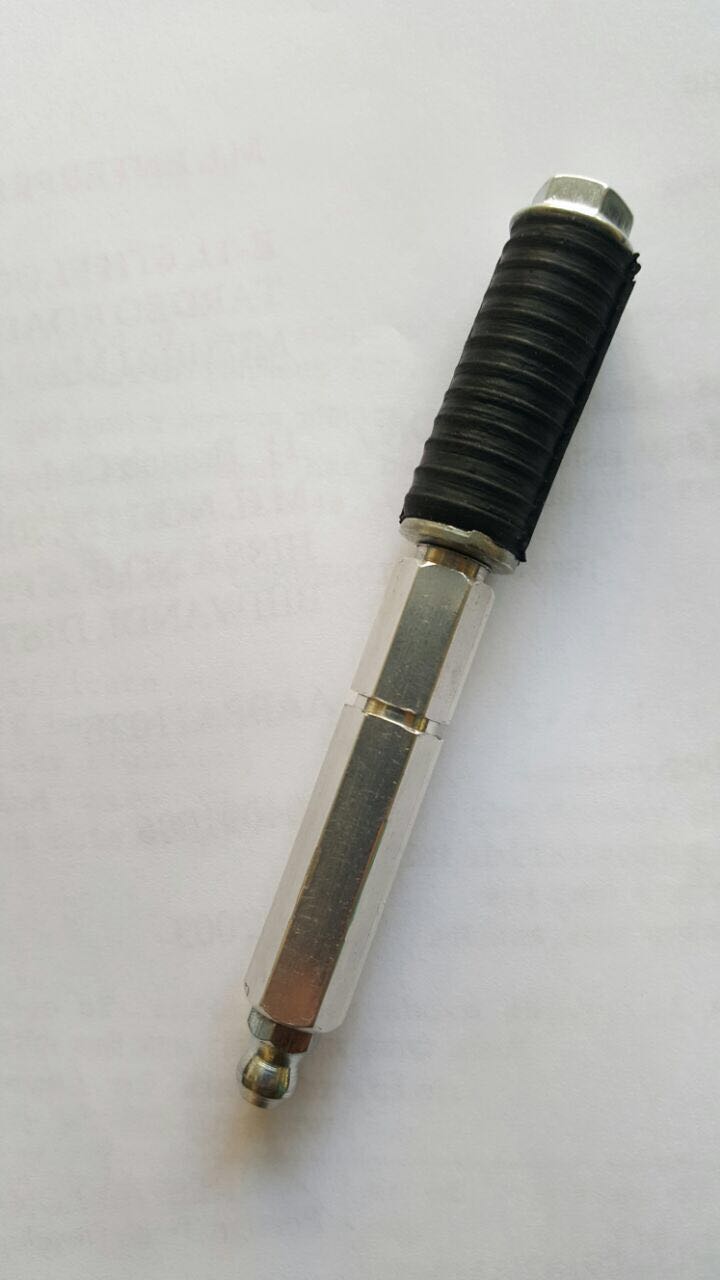

Steel Injection Packers

Product Description

High Pressure Steel Mechanical Injection Packer is use for concrete crack repairs, waterproofing, rehabilitation of concrete structures, basement leak sealing crack sealing etc. It matched with high pressure injection pump, suits for both polyurethane and epoxy injection.

Parameter of this High Pressure Steel Mechanical Injection Packer

The following is about High Pressure Steel Injection Packer related, I hope to help you better understand High Pressure Steel Injection Packer.

Specification of High Pressure Steel Mechanical Injection Packer

| Item No. | Length(mm) | Rubber diameter(mm) | Drill Bit diameter(mm) |

| CE -95 | 100 | 9.5 | 10 |

| CE- 135 | 100 | 13.5 | 14 |

| CE- 135 | 115 | 13.5 | 14 |

| CE- 135 | 150 | 13.5 | 14 |

| CE- 135 | 200 | 13.5 | 14 |

| CE- 135 | 250 | 13.5 | 14 |

| CE- 135 | 300 | 13.5 | 14 |

Aluminum Injection Packers

Product Description

High Pressure Aluminum Mechanical Injection Packer is use for concrete crack repairs, waterproofing, rehabilitation of concrete structures, basement leak sealing crack sealing etc. It matched with high pressure injection pump, suits for both polyurethane and epoxy injection.

Parameter of this High Pressure aluminum Mechanical Injection Packer

The following is about High Pressure aluminum Injection Packer related, I hope to help you better understand high Pressure aluminum Injection Packer.

Specification of High Pressure Steel Mechanical Injection Packer

| Item No. | Length(mm) | Rubber diameter(mm) | Drill Bit diameter(mm) |

| CE -95 | 100 | 9.5 | 10 |

| CE- 135 | 100 | 13.5 | 14 |

| CE- 135 | 115 | 13.5 | 14 |

| CE- 135 | 150 | 13.5 | 14 |

| CE- 135 | 200 | 13.5 | 14 |

| CE- 135 | 250 | 13.5 | 14 |

| CE- 135 | 300 | 13.5 | 14 |

Brass Injection Packers

Product Description

The design of the grease nipple type brass packer incorporates a non-return valve in the lower portion of the packer. When the resin has set, the top of the packer simply unscrews. This enables the base to be left in place leaving a small recess which can easily be filled using epoxy paste. The hook on type has the non-return ball valve located in the head and this can simply be removed enabling the operative to relieve the water pressure within the structure prior to injection.

- Brass Injection Packers, also known as mechanical packers, are suitable for repairing cracked foundations using high pressure injection, typically at 1,000 to 10,000 PSI.

- Are placed in holes drilled at 45 degrees to intersect the interior of the crack.

- Each Injection Packer locks into the drilled concrete hole by compressing the rubber sleeves surrounding the threaded brass or steel body, ensuring that it seals quickly and tightly at pressures of several thousand PSI.

- Injection Packer size depends on a crack’s depth and the volume of material needed.

Available Injection Packer Sizes:

- 3/8″ x 2.75″

- 1/2″ x 2.75″

- 1/2″ x 4″

- 5/8″ x 2.75″

Button /Flat head Injection Packers

Product Description

High Pressure Steel Mechanical Button /Flat Head Injection Packer is use for concrete crack repairs, waterproofing, rehabilitation of concrete structures, basement leak sealing crack sealing etc. It matched with high pressure injection pump, suits for both polyurethane and epoxy injection.

Parameter of this High Pressure Steel Button/Flat Head Mechanical Injection Packer

The following is about High Pressure Steel Injection Packer related, I hope to help you better understand High Pressure Steel Injection Packer.

Specification of High Pressure Steel Mechanical Injection Packer

| Item No. | Length(mm) | Rubber diameter(mm) | Drill Bit diameter(mm) |

| CE -95 | 100 | 9.5 | 10 |

| CE- 135 | 100 | 13.5 | 14 |

| CE- 135 | 115 | 13.5 | 14 |

| CE- 135 | 150 | 13.5 | 14 |

| CE- 135 | 200 | 13.5 | 14 |

| CE- 135 | 250 | 13.5 | 14 |

| CE- 135 | 300 | 13.5 | 14 |

| CE- 175 | 100 | 17.5 | 18 |

| CE- 175 | 150 | 17.5 | 18 |

| CE- 175 | 200 | 17.5 | 18 |

| CE- 175 | 300 | 17.5 | 18 |

Steel Combi Packer

The Crack Experts packer is a two-part steel packer consisting of a packer head and a packer body. The packer head consists of a screw and a sealing rubber, the packer body consists of a nut and a lubricator. The packer can be provided with a spherical or flat round lubricator. Assembly and disassembly of the packer is very easy due to its construction.

Crack Experts packers are produced in diameters of sealing rubbers 10-17 mm, lengths of 70-500 mm and in versions of the inner screw M5, M6 and M8

Plastic Packer -Hammer in injection packers

Product Description

PRODUCT DESCRIPTION of Hammer Injection Packer

Hammer Injection Packer made by PA66 material, drill holes by 10mm driller, fix the packer into the holes by #5 electric hammers. And working pressure not exceeds 200bar.

The use of Hammer Injection Packer

The Hammer-In port (Bang in Packer) is 3/8” (10mm) or 1/2” (13mm). The ports are inserted into the drill hole with the tap of a hammer. These packers do away with the sleeve and compression sleeve mechanism as the plastic body of the packer itself creates a compression seal. The packers are set very quickly increasing productivity on the job site. Due to the lower friction fit, injection pressures are limited with this packer type.

5/8" Plastic Hammer-in Button head Packers

Product Description

PRODUCT DESCRIPTION of Hammer-in Button head Packer

Hammer Injection Packer made by Nylon Material, drill holes by 16mm driller, fix the packer into the holes by #5 electric hammers. And working pressure not exceeds 250bar.

The use of Hammer-in Button head Packer

The Hammer-In port (Bang in Packer) is 5/8” (16mm) .The ports are inserted into the drill hole with the tap of a hammer. These packers do away with the sleeve and compression sleeve mechanism as the plastic body of the packer itself creates a compression seal. The packers are set very quickly increasing productivity on the job site. Due to the lower friction fit, injection pressures are limited with this packer type.

Surface Adhesive Packers

ADHESIVE SURFACE PACKERS:

also, called as ‘surface PACKER PORTS’ used for epoxy injection at low injection pressures. They are glued to the concrete surface usigan epoxy adhesive. The port inlet is fitted with non-return nipples that prevent the epoxy to flow back. This type of packer is normally used on dry condition for hairline cracks to wider cracks in dry conditions.

Application Instructions:(Adhesive Packers):

– Identify and mark the length of the crack area to be injected, then open the crack by grinder.

– Clean the substrate with wire brush at a distance of 25mm on both sides of the crack. Wire brush is recommended

because grinders often leave dust in the crack.

-Measure the width of crack in order to determine the correct product to be injected.

-Once crack is exposed, clean and dry; you may adhere to adhesive packers.

-Adhesive packers or surface ports are recommended for wide or surface cracks and clear in nature cracks; and when the substrate thickness is small and will be dependent on a slow operating injecting pressures.

– Adhesive packers are typically placed at 20mm spacing, with increase spacing up to 50mm on wider cracks.

-The packers are secured to the crack with epoxy paste/sealer.

-Prepare and mix the two components of epoxy paste1:1 ratio until achieving a uniform homogeneous gray compound.

-Using a spatula, apply the mixed epoxy paste across the surface of the crack on a band of 50mm. Be sure not to cover the bottom opening of the packer with paste as this will prohibit the flow of resin into the crack. -Once the epoxy paste is fully cured, you are ready to connect the injection pump.

-On a clean container, mix the two components of epoxy resin with a slow speed electric drill fitted with mixing paddle until a homogeneous mixture is achieved.

– Pour the mixture of epoxy resin onto the tank of the Injection Pump ready to inject.

-On initial injection process, pump out the few drops of material on a separate container so as to make sure material is oozing from the nozzle properly.

-Start injecting at the lowest packer of the crack length, while leaving the above packer open.

-Connect the injection pump onto the adhesive packer and commence injection process.

-Vertical cracks are typically injected from the bottom up, while horizontal crack injections are commonly initiated at the point of widest crack width.

-Continue to pump the epoxy resin into the adhesive packer until you see material exiting from the adjacent packer. At this time, closed the adjacent packer with nipple and fix the injection pump and continue the injection process until the length of the crack is fully injected.

-After all the packers/ports are injected, it is recommended to allow adequate time for the epoxy resin to completely cure.

-Adhesive packers/ports can be removed by grinding.

Product Description Adoration Injection Packers are filling valves or ports and connection pieces between the injection equipment and the structure. One way valves (i.e. Zerk or button head fittings), are located on the top of the injection packer and connect to the injection equipment.

Uses Adoratoin Injection Packers serve as filling valves or ports and connection pieces between the injection equipment and the structure when sealing structures or repairing cracks by injection. They can be used for the injection of various mat

Characteristics / Advantages A full range of Adoration Injection Packers are available (Mechanical and Surface Packers) Designed to accommodate and withstand the relevant pressures and flow rates without leaking or ”jumping-off".

Mechanical Borehole packers

Product Description

Mechanical Bore hole Packers sometimes called Surface Set Packers, are a low cost, low pressure, hand set Packer for Cased Wells, or Smooth Hard Rock Bored Holes. They are made to be set at 12” depth to 20’ depth. The length is decided by where seal is going to be down hole. They have a limited expansion range, that is why they are not recommended to be used in Open Holes.

Mechanical Bore hole Packers are operated by tightening a nut on the surface and forcing two pipes to work against each other, which compresses the rubber gland to form a seal. Mechanical Packers are used for Freeze Plugs, Low Pressure Injection, Grouting, Air Sparging, and to control flows out of Artesian Wells. You can adapt Gages, Valves etc. to meet your needs. Made of S.S. & Neoprene Rubber, or if not a factor, can be made with standard pipe. Made to fit the I.D. of the Casing size you are using.

Example, 1.85” O.D. to fit in 2” Sch.40 I.D. casing, 3.75” O.D. for 4” Sch.40 I.D. casing.

Inflatable Grout Packers

Inflatable packers are available in diameter sizes of 1"- 2", 2"- 3", 3" – 4", 3"- 6", 4"- 7" and 5"- 8". Lengths range from 14" up to five feet or more. With their sliding head design, they have the ability to double in size from their run-in diameter and typically furnish a longer seal than that of a mechanical packer. These packers have integral tube scrapers that remove excess grout that has adhered to the outside of the center tube and work each time the packer is deflated.

New Grouting Packers

Product Description

| Model | Injection packers |

| Brand | CRACKEXPERTS |

| Length | 70mm |

| Diameter(Nipple) | 16mm |

| Material | Steel |

16x70mm Steel Hat Injection Packers , the nipple can be removed or fixed according to your requirements.